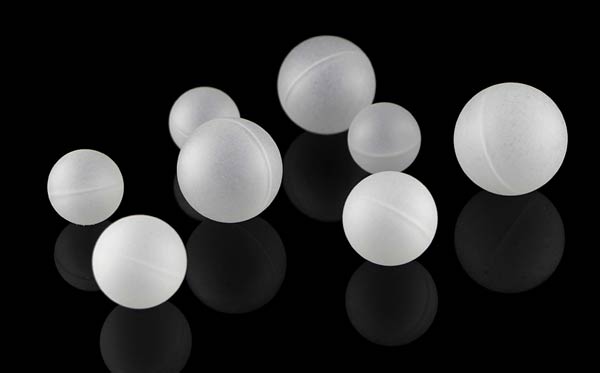

Plastic deodorant is a highly concentrated odor absorber, mainly for nitrogen-containing and sulfur-containing small molecule odor gases, and can be used in the production and processing of color masterbatch and modified plastics; especially suitable for polyolefin, compound rubber processing and nylon and other wastes The plastic recycling process; it can also reduce the odor emitted in the process of dispersing pigments such as ultramarine and yellow pigments and oxidized carbon black in the resin.

Performance and characteristics of plastic deodorant agents: In the process of producing and processing polymers and coatings, a small amount of small molecular organic matter is often added to polymers or coatings. These small organic molecules can change the properties of polymers and even become a health hazard. Plastic deodorant is a deodorant that combines absorption and reaction. At the same time, it has good dispersibility. Different from other methods, the use of deodorant agents can completely eliminate the odors of PP, PE, PVC, ABS, PS plastics, rubber and other odors of the paint, instead of covering them with other odors.

The main industries involved are: automobiles, food packaging films, masterbatch factories, plastic and elastomer modification, beverage bottles, caps, etc., production or use of vulcanized rubber, odors generated by adding antistatic agents, and other industries that are sensitive to odors.